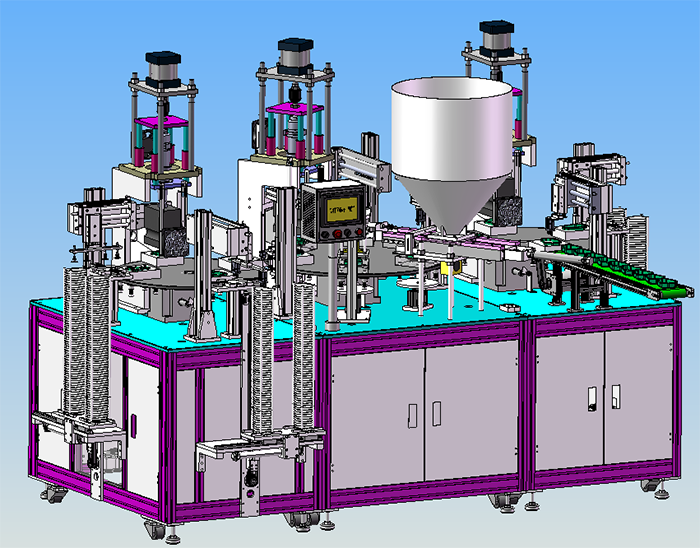

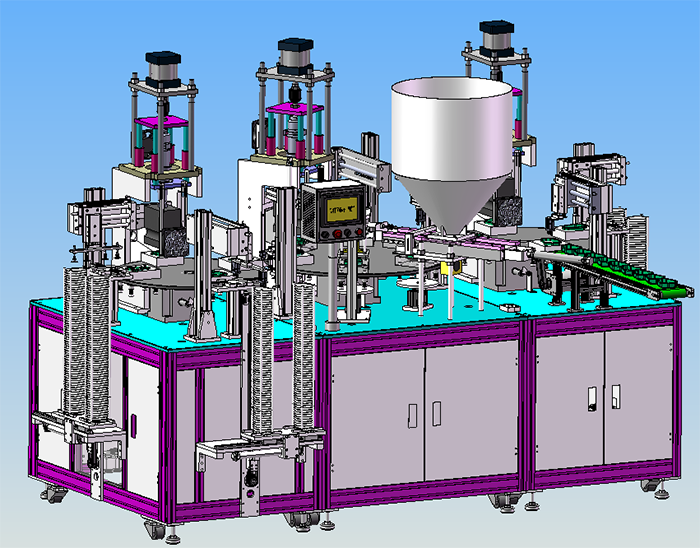

This machine is used for the quantitative charging of carbon powder and the upper cover of the carbon box of the gas mask. The ultrasonic welding of the upper cover and the 3 turntable multi-station one-out design; the ultrasonic welding of the bottom box and the compression cotton, and the assembly of the upper cover and the compression cotton Ultrasonic welding. The assembly of the upper cover and the bottom box. Carbon loading and ultrasonic welding. The process flow is: manual feeding of the bottom box to the feeding belt, automatic manipulator clamping and feeding to the turntable fixture. The bottom box compression cotton is automatically loaded and assembled. Ultrasonic welding. Manipulator transfers the bottom box to another turntable fixture. Automatic carbon loading, automatic pressure vibration leveling, automatically installs the cover, and the upper cover is automatically loaded. The bottom box is automatically loaded and assembled with compressed cotton. Ultrasonic welding. The robot transfers the upper cover To another turntable fixture and bottom box assembly. Ultrasonic welding, automatic cutting and collection, manual introduction of the carbon powder into the large-capacity stainless steel hopper box, automatic linear ejection of the metering cup. The pneumatic vibrator is used to ensure the stability and stability of the carbon powder. . Consistency. Simple and convenient operation. Safe to use,. PLC control. Touch screen display operation. No bottom box automatic identification and no powder protection,

Technical parameters.

1. Capacity: 12-15 pcs/min;

2. Operator: 1 person.

3. Powder volume: customized according to volume of powder,

4. Bottom box and upper cover fixture: customized according to product appearance.

5. Welding method: Ultrasonic 15K; 3 sets.

6. Power supply: AC220 V 12KW.

7. Air source: 0.6~0.8 MPa 30L/MIN. Intake pipe: φ12.

8. Vacuum source: -90Kpa~-60Kpa 5L/MIN. Inlet pipe: φ12.

8. Dimensions MM: length 3000*width 1400*height 1800.

9. Weight: 1500Kg.

This machine is used for the quantitative charging of carbon powder and the upper cover of the carbon box of the gas mask. The ultrasonic welding of the upper cover and the 3 turntable multi-station one-out design; the ultrasonic welding of the bottom box and the compression cotton, and the assembly of the upper cover and the compression cotton Ultrasonic welding. The assembly of the upper cover and the bottom box. Carbon loading and ultrasonic welding. The process flow is: manual feeding of the bottom box to the feeding belt, automatic manipulator clamping and feeding to the turntable fixture. The bottom box compression cotton is automatically loaded and assembled. Ultrasonic welding. Manipulator transfers the bottom box to another turntable fixture. Automatic carbon loading, automatic pressure vibration leveling, automatically installs the cover, and the upper cover is automatically loaded. The bottom box is automatically loaded and assembled with compressed cotton. Ultrasonic welding. The robot transfers the upper cover To another turntable fixture and bottom box assembly. Ultrasonic welding, automatic cutting and collection, manual introduction of the carbon powder into the large-capacity stainless steel hopper box, automatic linear ejection of the metering cup. The pneumatic vibrator is used to ensure the stability and stability of the carbon powder. . Consistency. Simple and convenient operation. Safe to use,. PLC control. Touch screen display operation. No bottom box automatic identification and no powder protection,

This machine is used for the quantitative charging of carbon powder and the upper cover of the carbon box of the gas mask. The ultrasonic welding of the upper cover and the 3 turntable multi-station one-out design; the ultrasonic welding of the bottom box and the compression cotton, and the assembly of the upper cover and the compression cotton Ultrasonic welding. The assembly of the upper cover and the bottom box. Carbon loading and ultrasonic welding. The process flow is: manual feeding of the bottom box to the feeding belt, automatic manipulator clamping and feeding to the turntable fixture. The bottom box compression cotton is automatically loaded and assembled. Ultrasonic welding. Manipulator transfers the bottom box to another turntable fixture. Automatic carbon loading, automatic pressure vibration leveling, automatically installs the cover, and the upper cover is automatically loaded. The bottom box is automatically loaded and assembled with compressed cotton. Ultrasonic welding. The robot transfers the upper cover To another turntable fixture and bottom box assembly. Ultrasonic welding, automatic cutting and collection, manual introduction of the carbon powder into the large-capacity stainless steel hopper box, automatic linear ejection of the metering cup. The pneumatic vibrator is used to ensure the stability and stability of the carbon powder. . Consistency. Simple and convenient operation. Safe to use,. PLC control. Touch screen display operation. No bottom box automatic identification and no powder protection,